According to the World Health Organization, about 785 million people around the world lack a clean source of drinking water. Despite the vast amount of water on Earth, most of it is seawater and freshwater accounts for only about 2.5% of the total. One of the ways to provide clean drinking water is to desalinate seawater. The Korea Institute of Civil Engineering and Building Technology (KICT) has announced the development of a stable performance electrospun nanofiber membrane to turn seawater into drinking water by membrane distillation process.:

Membrane wetting is the most challenging issue in membrane distillation. If a membrane exhibits wetting during membrane distillation operation, the membrane must be replaced. Progressive membrane wetting has been especially observed for long-term operations.

If a membrane gets fully wetted, the membrane leads to inefficient membrane distillation performance, as the feed flow through the membrane leading to low-quality permeate.

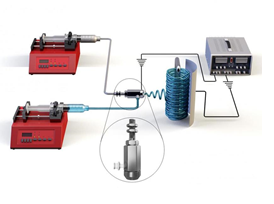

A research team in KICT, led by Dr. Yunchul Woo, has developed co-axial electrospun nanofiber membranes fabricated by an alternative nano-technology, which is electrospinning. This new desalination technology shows it has the potential to help solve the world’s freshwater shortage. The developed technology can prevent wetting issues and also improve the long-term stability in membrane distillation process. A three-dimensional hierarchical structure should be formed by the nanofibers in the membranes for higher surface roughness and hence better hydrophobicity.

The co-axial electrospinning technique is one of the most favorable and simple options to fabricate membranes with three-dimensional hierarchical structures. Dr. Woo’s research team used poly(vinylidene fluoride-co-hexafluoropropylene) as the core and silica aerogel mixed with a low concentration of the polymer as the sheath to produce a co-axial composite membrane and obtain a superhydrophobic membrane surface. In fact, silica aerogel exhibited a much lower thermal conductivity compared with that of conventional polymers, which led to increased water vapor flux during the membrane distillation process due to a reduction of conductive heat losses.

Most of the studies using electrospun nanofiber membranes in membrane distillation applications operated for less than 50 hours although they exhibited a high-water vapor flux performance. On the contrary, Dr. Woo’s research team applied the membrane distillation process using the fabricated co-axial electrospun nanofiber membrane for 30 days, which is 1 month.

The co-axial electrospun nanofiber membrane performed a 99.99% salt rejection for 1 month. Based on the results, the membrane operated well without wetting and fouling issues, due to its low sliding angle and thermal conductivity properties.

The co-axial electrospun nanofiber membrane performed a 99.99% salt rejection for 1 month. Based on the results, the membrane operated well without wetting and fouling issues, due to its low sliding angle and thermal conductivity properties.

Temperature polarization is one of the significant drawbacks in membrane distillation. It can decrease water vapor flux performance during membrane distillation operation due to conductive heat losses. The membrane is suitable for long-term membrane distillation applications as it possesses several important characteristics such as, low sliding angle, low thermal conductivity, avoiding temperature polarization, and reduced wetting and fouling problems whilst maintaining super-saturated high water vapor flux performance.

Dr. Woo’s research team noted that it is more important to have a stable process than a high-water vapor flux performance in a commercially available membrane distillation process. Dr. Woo said that “the co-axial electrospun nanofiber membrane have strong potential for the treatment of seawater solutions without suffering from wetting issues and may be the appropriate membrane for pilot-scale and real-scale membrane distillation applications.”

Reference:

https://www.chemeurope.com/en/news/1171742/making-seawater-drinkable-in-minutes.html

The economic impact of biosimilars on the Australian health care system is now clearer, with data revealing their role in reducing market expenditure and driving price competition.

The Chinese Golden Week impacts Ocean Freight Shippers for two main reasons:

Donald Trump’s tariffs of 50% have come into force on most US imports from India. India’s giant generic pharmaceuticals sector and its electronics and petroleum products are exempt from the tariffs. Aluminium, steel and copper remain at 25%, but job-heavy sectors such as textiles, jewellery, seafood and leather are squarely in the line of fire.

The European Chemicals Agency (ECHA) has published the updated proposal to restrict per- and polyfluoroalkyl substances (PFAS) under the EU’s chemicals regulation, REACH. The update has been prepared by the authorities from Denmark, Germany, the Netherlands, Norway and Sweden, who submitted the initial proposal in January 2023.

Most chemicals exported from the 27 member countries of the European Union into the US will be subject to a 15% tariff on top of their selling prices under an agreement signed on July 27 between the US and the European Commission.

We’re thrilled to announce a new strategic alliance between ExSyn, Exim-Indis and simABs, a leading EU-based biologics manufacturer known for its patented continuous flow technology in antibody production.

The global trade landscape is undergoing significant changes following the announcement of new reciprocal tariffs by the United States government. Recent developments indicate significant shifts in global trade dynamics, with key policy adjustments, ongoing negotiations, and evolving logistics patterns. Below is a summary of the latest developments.

In January 2025, the US FDA published a draft regulatory guidance entitled “The Considerations for Use of Artificial Intelligence to Support Regulatory Decision-Making for Drug and Biological Products”.

The adoption of artificial intelligence (AI) and large language models (LLMs) is rapidly reshaping clinical research and drug development.